FILTER. PRODUCT CATEGORY.

FILTER. PROCESSES.

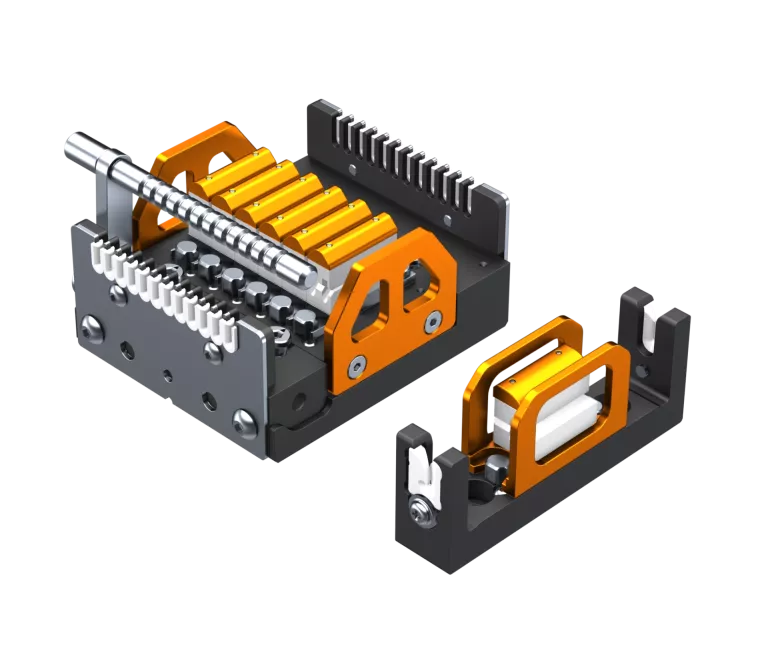

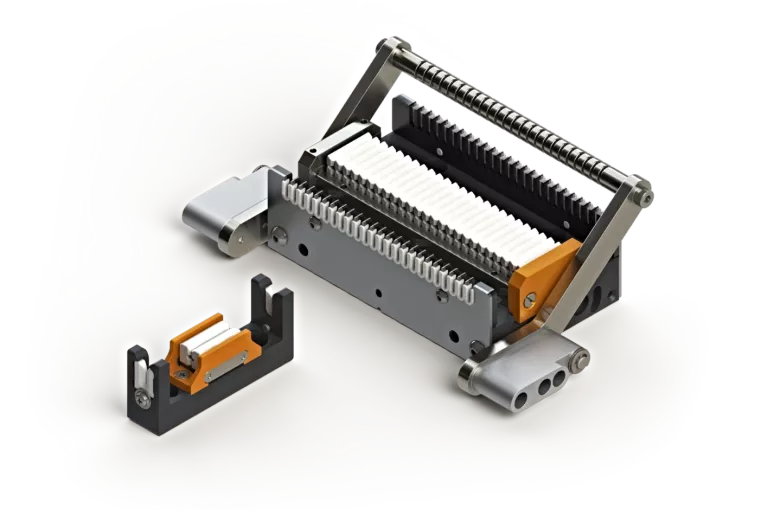

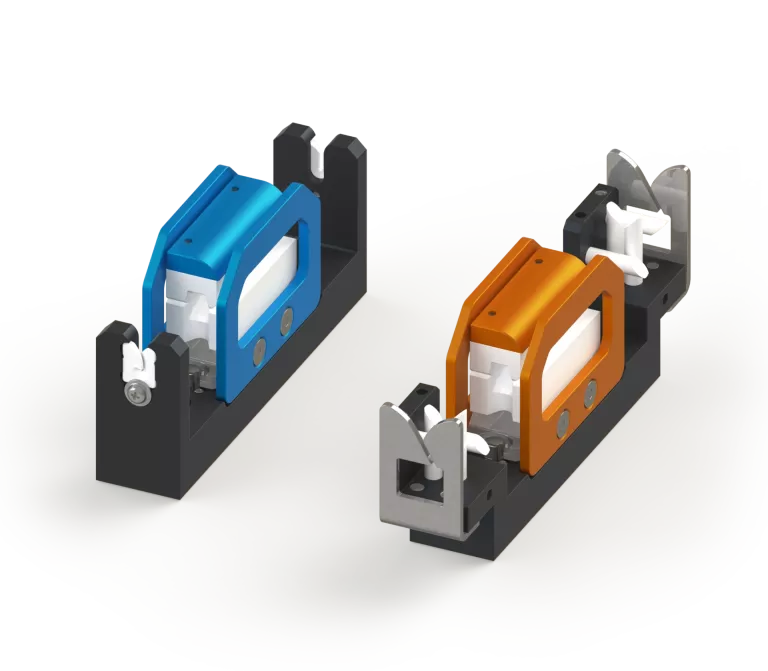

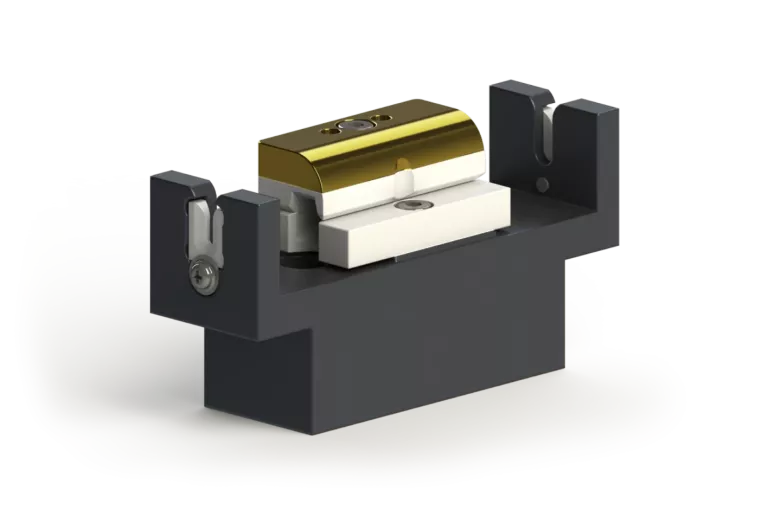

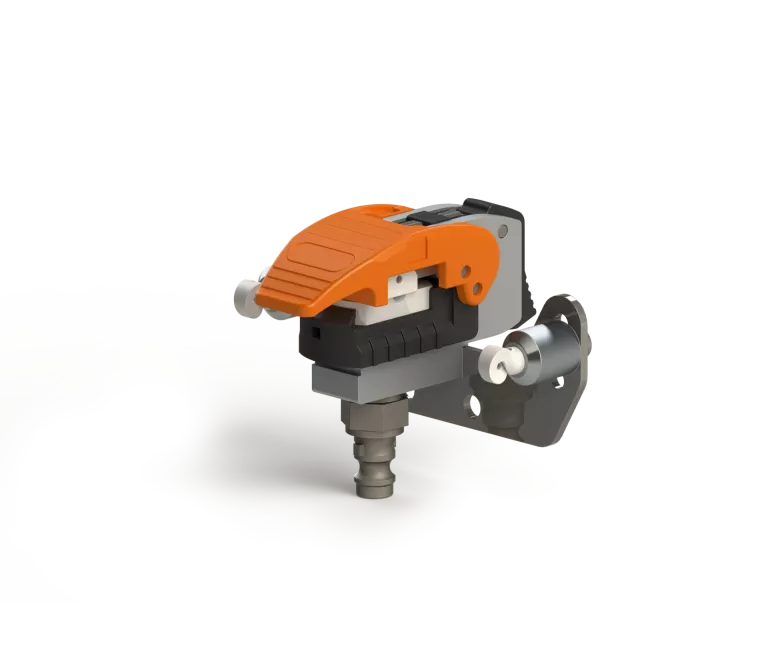

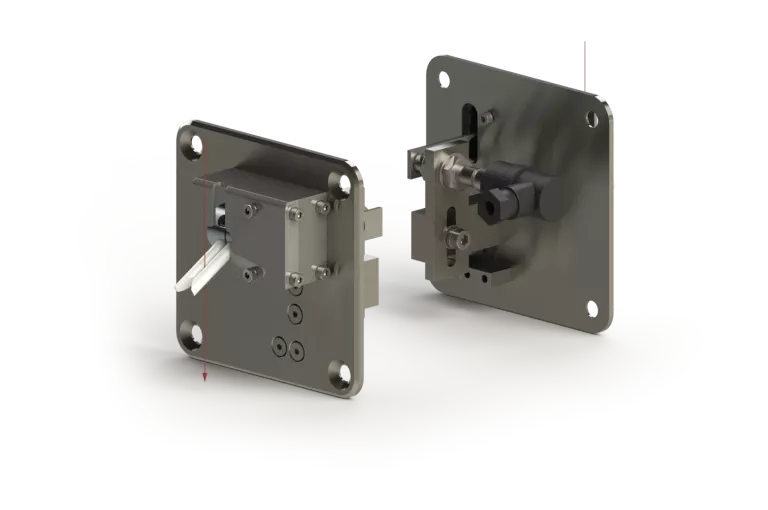

PolyJet-SP-3

The PolyJet-SP-3 air interlacing jet raises the bar in terms of handling and process reliability. The unique quick-release system allows jet packs to be removed with just a single 180° turn. Different variants for 1, 2, 4, 6, 8, 10, 12, 16, 20, 24 or 32 threads are available on request. Depending on the jet type, multiple jets with thread line spacing of 4, 6, 8, 10 or 12 mm are also available.

View Details

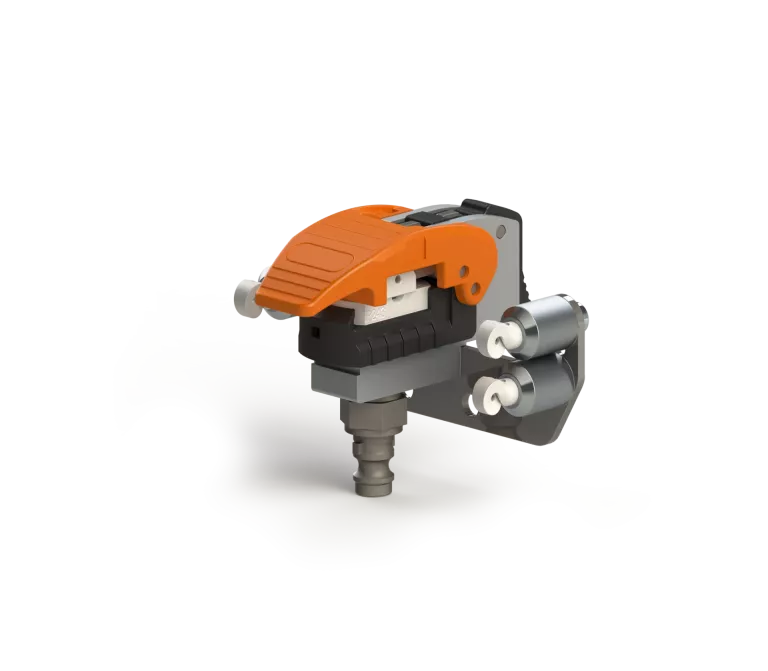

PolyJet-SP-3 Migra

The PolyJet-3 Migra not only ensures uniform distribution from the spinning preparation through to the yarn core, it also increases efficiency in downstream processes. Thanks to the ingenious quick-fastening system, jet packs can be removed with a single 180° turn.

View Details

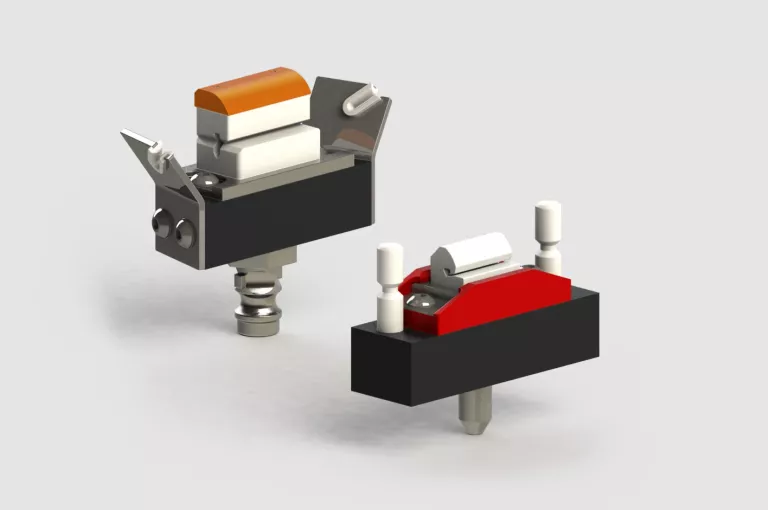

PolyJet-SP-2 / PolyJet-SP-2 Migra

The PolyJet-SP-2 allows jets of different sizes and interlacing characteristics to be replaced on the same holder. This allows a quick response to changing market trends. Different variants for 1, 2, 4, 6, 8, 10, 12, 16, 20, 24 or 32 threads are available on request. Depending on the jet type, multiple jets with thread line spacing of 4, 6, 8, 10 or 12 mm are also available.

View Details

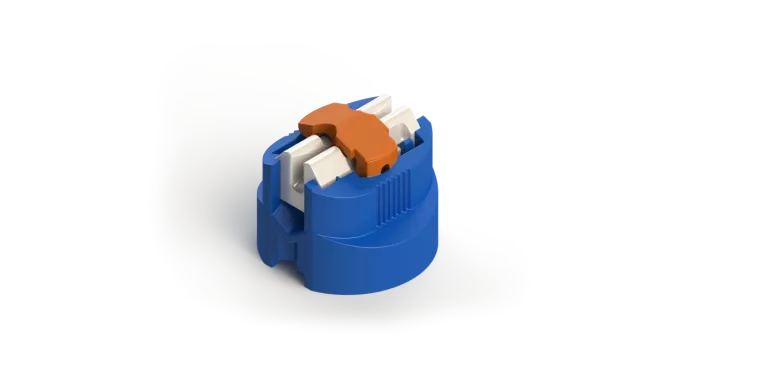

POY-Jet-SP

The POY-Jet-SP enables optimum interlacing performance and is versatile thanks to the well-established PolyJet-SP-2 jet connector. The yarn guides can be combined to meet virtually any customer requirement. The POY-Jet-SP is suitable for cost-optimised pre-interlacing or interlacing of POY yarns.

View Details

FDY-Jet-SP

A cost-effective interlacing jet for an application range up to max. 190 dtex. The connector is compatible with all jet packs from the PolyJet-SP-2 series. This ensures maximum flexibility. If requirements change, only the jet packs need to be exchanged.

View Details

MIG-Jet-SP

The MIG-Jet-SP air migration jet uses compressed air to slightly compact the individual filaments of a multi-filament yarn without creating interlacing points. At the same time, the compressed air spreads the unevenly distributed spin finish uniformly right into the yarn core. This results in smooth yarn running and allows higher processing speeds.

View Details

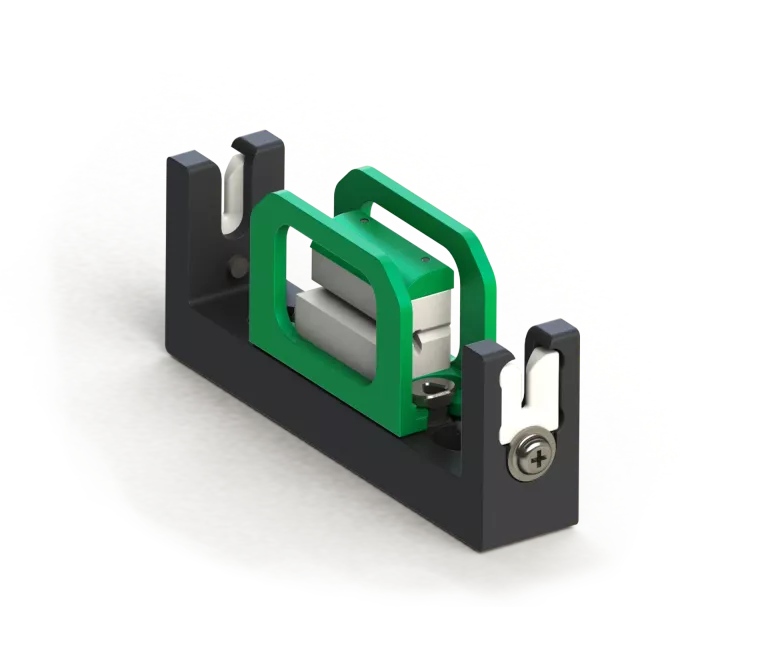

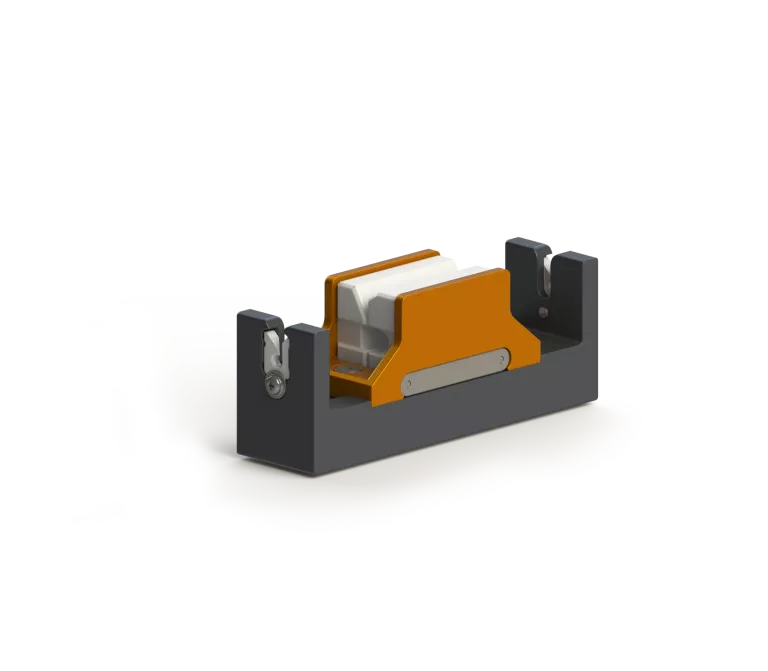

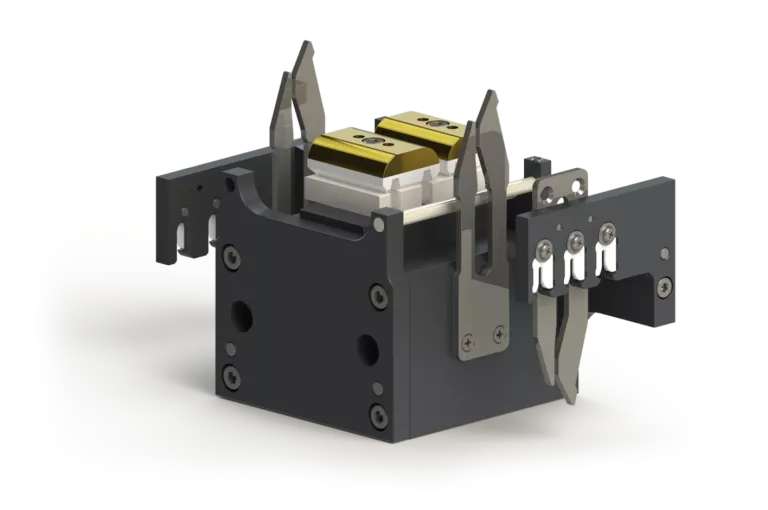

PolyJet-TG-3

High-performance air interlacing jets for technical yarns. The unique quick-release system allows jet packs to be removed with just a single 180° turn. The lateral threading slot ensures maximum operational reliability. The jets are characterised by a compact, space-saving design and include a roll bar to protect the ceramic surfaces.

View Details

PolyJet-TG-2 / PolyJet-TG-2 Migra

The PolyJet-TG-2 allows different jets types to be easily changed, enabling a rapid response to shifting market trends. The product range covers various requirements for interlacing characteristics. The universal holder ensures durability and robustness.

View Details

FDY-Jet-TG

The FDY-Jet-TG achieves a high interlacing performance, and its design is reduced to the essentials. Maximum functionality and durability as well as a robust design ensure consistent results. The jet is especially recommended for the interlacing of technical multifilament yarns made of polyester, polyamide, and polypropylene in all spin-draw processes.

View Details

MIG-Jet-TG

The MIG-Jet-TG is used in the spinning process for spin-finish migration in textile, technical, and BCF (Bulked Continuous Filament) yarns. Its robust design ensures consistent results and a long service life.

View Details

PolyJet-TG TopAir

The PolyJet-TG Top Air is used for advanced air interlacing of technical filament yarns made of polyester, nylon, and polypropylene which can be used, for example, in the manufacture of ropes, geo-textiles, hoses, sewing threads, and netting.

View Details

PolyJet-BCF TopAir

The PolyJet-BCF TopAir is used for the improved air interlacing of BCF yarns made of polyester, nylon, and polypropylene, which are used in the manufacture of carpets.

View Details

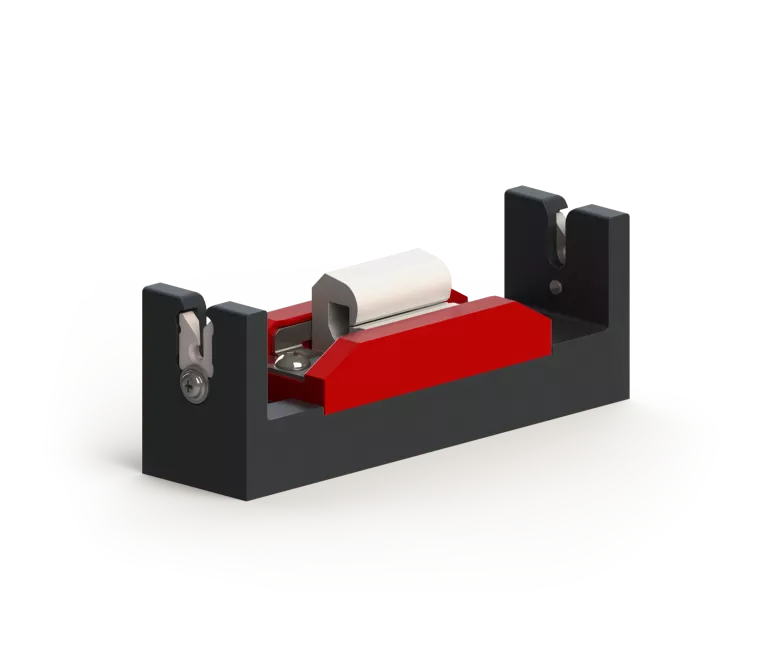

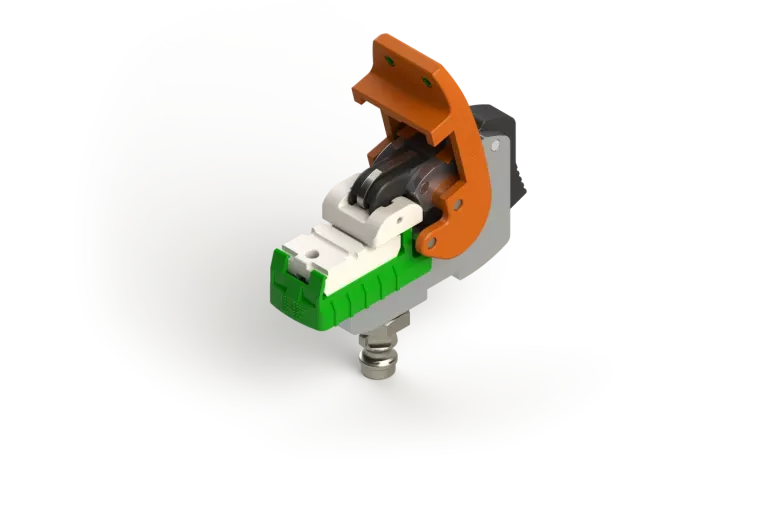

SlideJet-FT15-2

The SlideJet-FT15-2 is used in the manufacturing and processing of high value filament yarns in the false-twist texturing process. The jet is a modular system with a universal quick-lock housing and numerous easily replaceable jet inserts.

View Details

SlideJet-2T

The SlideJet-2T was specially developed for DTY systems with modified (two-in-one) winding stations. The jet is a modular system with a universal quick-lock housing and various easily replaceable jet inserts with two yarn channels.

View Details

SwissJet

The SwissJet is designed for the effective interlacing of multifilament yarns during false-twist texturing. The jet has a housing that is specially reinforced with carbon fibres which give it particularly great strength during operation, a long service life, and a very low weight. Various jet inserts are available for the different yarn types.

View Details

KFJet

The KF jet insert is the optimal solution for knot-free air interlacing of DTY yarns. Although the yarn is intermingled, it shows no visible interlacing knots. Consequently, the fabric does not have any interlacing knots, either.

View Details

DetorqueJet-3

The DetorqueJet-3 is a highly compact jet without moveable parts. The jet is placed after the set heater and before the third delivery shaft and can be used for both S and Z textured yarns.

View Details

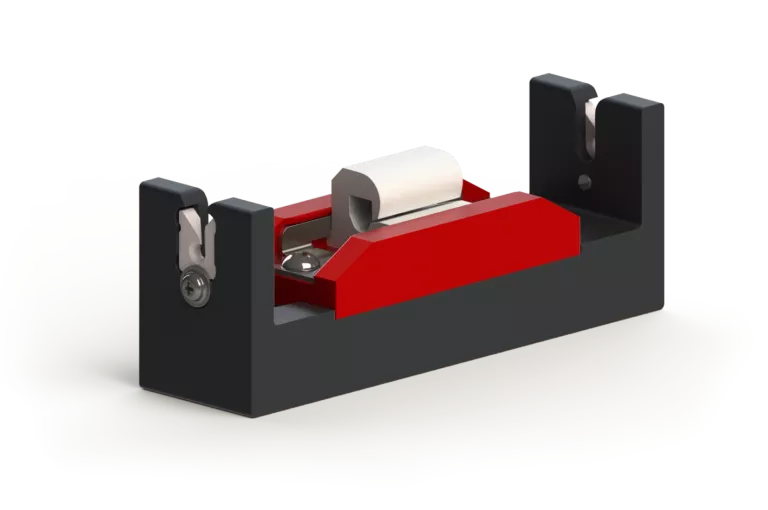

SlideJet-DT15-2

The SlideJet-DT15-2 is used in the high-quality manufacturing and processing of high value flat yarns. The jet is a modular system with a universal quick-lock housing and numerous easily replaceable jet inserts.

View Details

SlideJet-HFP15-2

The SlideJet-HFP15-2 is used during the cost-effective manufacture and processing of filament yarns during the air covering process. The jet is a modular system with a universal quick-lock housing and numerous easily replaceable jet inserts.

View Details

DSW-Jet

The DSW Jet offers vast potential for optimising existing machines. On the one hand, considerable air savings of up to 30% can be achieved in the DSY (differential shrinkage yarn) process. Combining FDY and POY yarn makes it possible to create interesting structural effects in the fabric. On the other hand, a higher number of knots as well as knot uniformity with the same air consumption can be achieved in the DW draw-packaging process for plain yarns when POY or FDY yarns are combined.

View Details

WarpJet-KV

The WarpJet is used for efficient interlacing during warping. The fast and simple threading from above is combined with easy cleaning and reduced machine downtimes.

View Details

TexJet-ATY

The TexJet-ATY produces superior yarn at high processing speeds. It is used for the production of very fine to coarse yarns made of polyester, polyamide, and polypropylene and in the production of high-grade flame and effect yarns.

View Details

HemaJet-LB06

The robust HemaJet-LB06 jet housing is compatible with all jet core series (T, A, S) of the previous products HemaJet-LB02 & -LB04, and thus offers a perfect combination for all requirements in air texturing processes. The distance between the impact body and the jet core can be easily adjusted using various gauges.

View Details

HemaJet jet cores ST series

The proven series of jet cores in hardened steel, especially designed for air texturing of glass-filament yarns. Air texturing uses air to intermingle the individual glass filaments of a multifilament yarn. This provides the yarn with greater volume. In addition to this structural change, multiple yarns with different features can also be blended at the same time. The end products can be used for both thermal and acoustic insulation.

View Details

ATYJet-RC

The ATYJet-RC combines the best of established HemaJet T-jet technology with a modern, performance-optimised design.

View Details

HemaJet-EO52

The HemaJet-EO52 is used in the production of high quality bulky air-textured yarns such as polyester, nylon, polypropylene, and glass fibres.

View Details

WettingHead

The wetting head is used to prepare the filament yarn to be textured in the air texturing process (ATY). The core thread is usually wetted during a specific process, especially in a process where core and effect yarn is air textured. The wetting process is used to soften the sizing agent (spin finish), which ultimately improves the texture. Many years of practical use with different machine configurations have shown that the wetting head ensures optimum water transfer to the yarn. The higher the total count range of the feed yarn, the more wetting that is required.

View Details

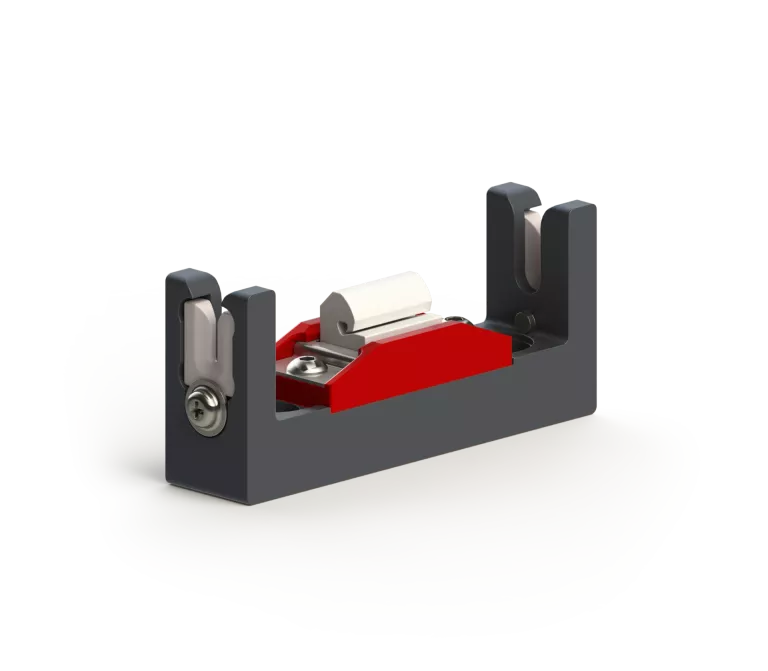

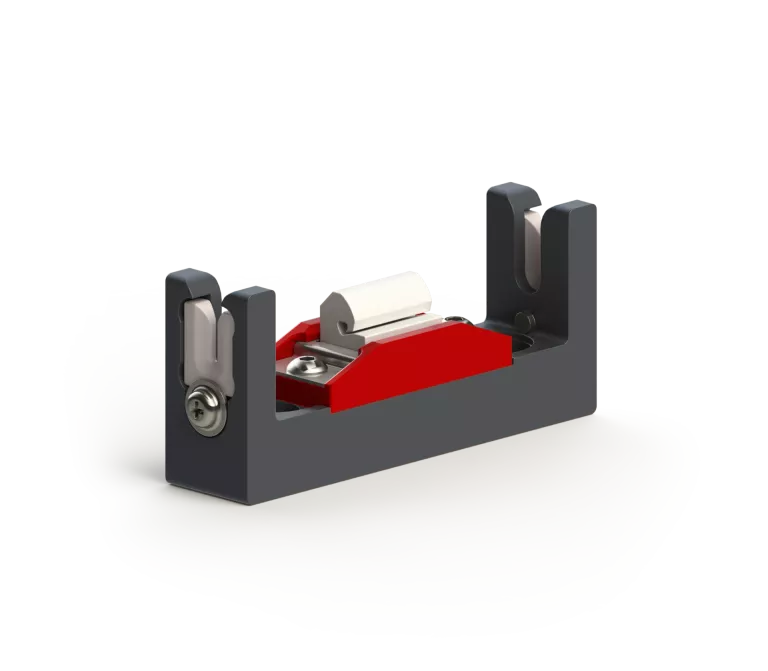

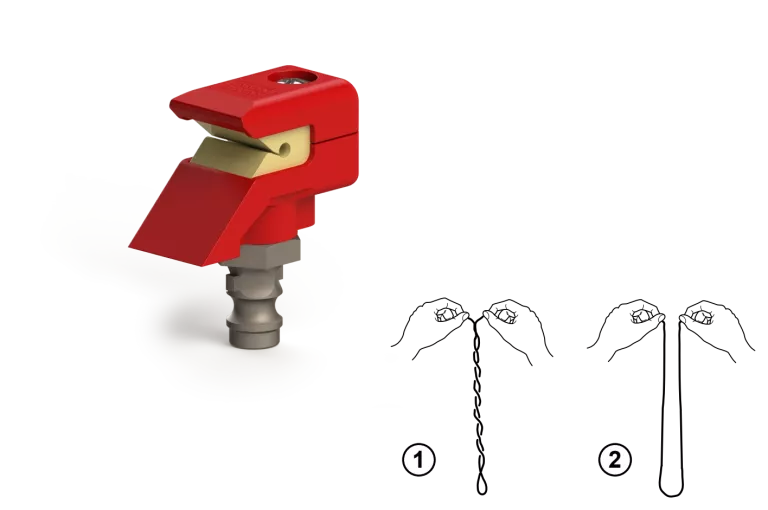

AirSplicer-POY

The light, robust splicer for splicing POY multifilament yarns during false-twist texturing (DTY). The integrated automatic splicing function guarantees maximum reproducibility. The resulting short, knot-free splices have a high degree of uniformity and strength and thus cause significantly fewer problems in downstream processes compared to buttoned splices.

View Details

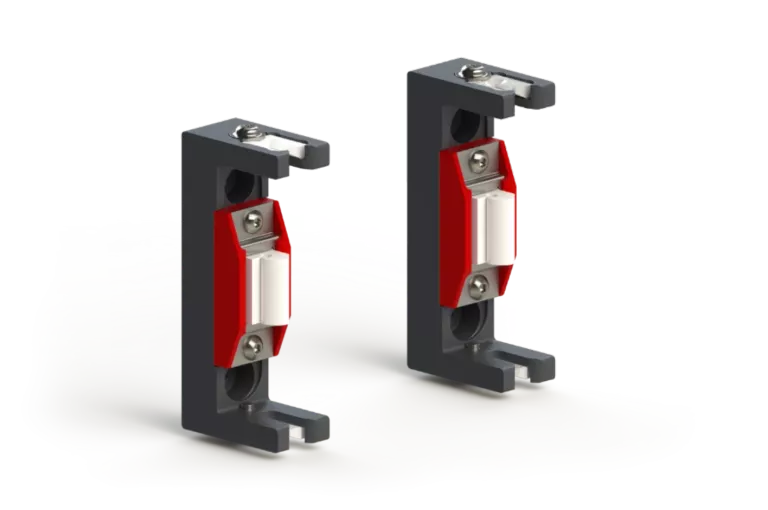

AirSplicer-3 Flex

The AirSplicer-3 Flex covers an exceptionally large count range when splicing textile and technical multifilament yarns. The unit's width can be adjusted to accommodate a wide variety of blow chambers (splice nozzles), depending on the type of material and splice strength requirements.The integrated automatic splicing system ensures maximum reproducibility of the splices. Wear parts, such as blades or thread clamps can be replaced very easily. The ergonomically shaped handle simplifies operation.

View Details

AirSplicer-17-2

The AirSplicer-17-2 produces a splice with flat, neatly bound yarn ends and maximum strength. Part-oriented, synthetic filament yarns (POY) can also be spliced, as can fine viscous or nylon fine hosiery yarns, fine carbon and glass fibre yarns, or BCF yarns.

View Details

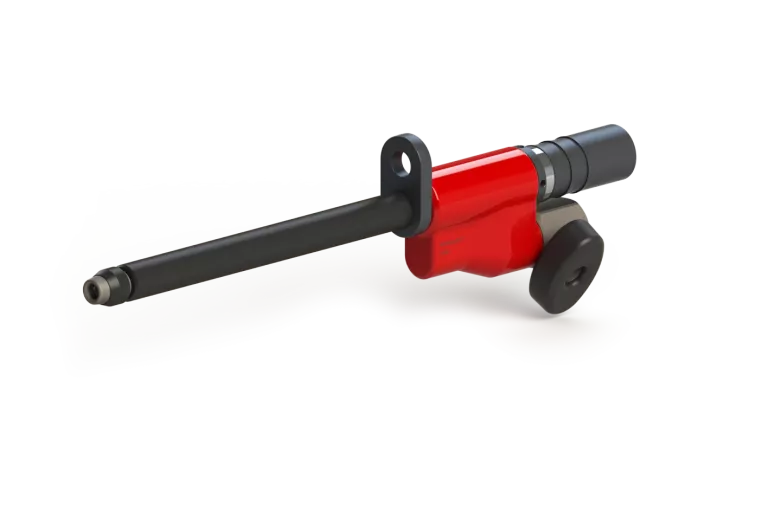

Lufan-3

The Lufan-3 is used for threading yarn on textile machines while they are operating. With products for the entire range of yarns and process parameters, our aspirators are in a class of their own. They stand out due to their low weight, extreme durability, and a remarkably powerful suction capacity.

View Details

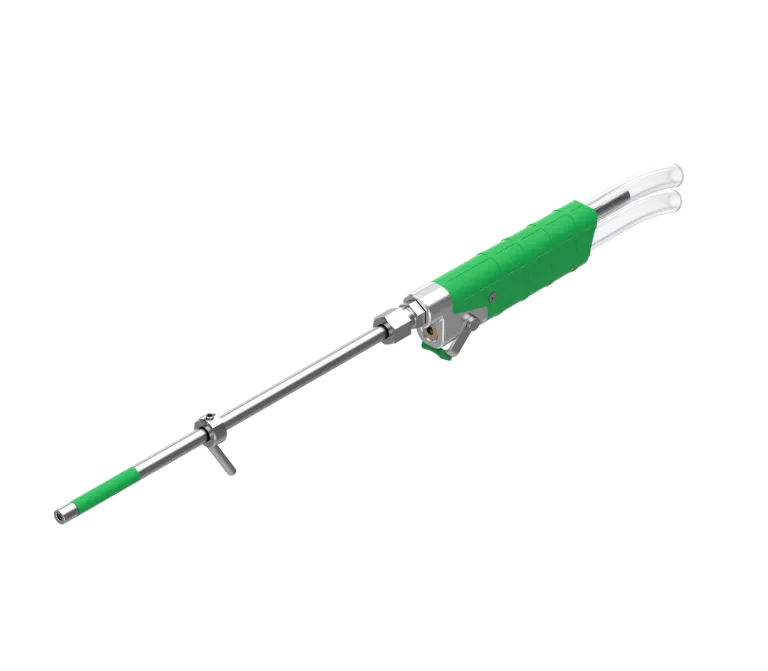

Lufan-4 Nano

For threading yarn in texturing (ATY, DTY) and air covering machines. The maximum total count is 3,000 dtex. The low weight and one-handed operation help machine operators thread the yarn. Angled suction tubes are available as options to make handling even more efficient.

View Details

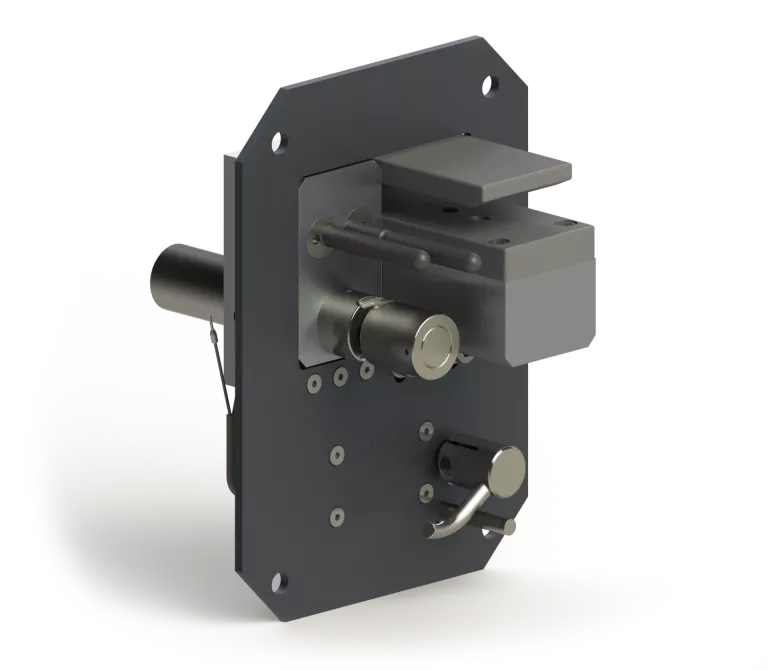

Splicing-cutting unit

The splicing unit simplifies the handling of individual ends when spinning them in or stringing them up in systems for manufacturing synthetic staple fibre tows. The new end to be threaded is spliced with the general tow in the vicinity of the single spinning position and then cut.

View Details

LufanStat

The LufanStat is used for aspirating, the LufanStat-Cut for aspirating and cutting yarns and cables.

View Details

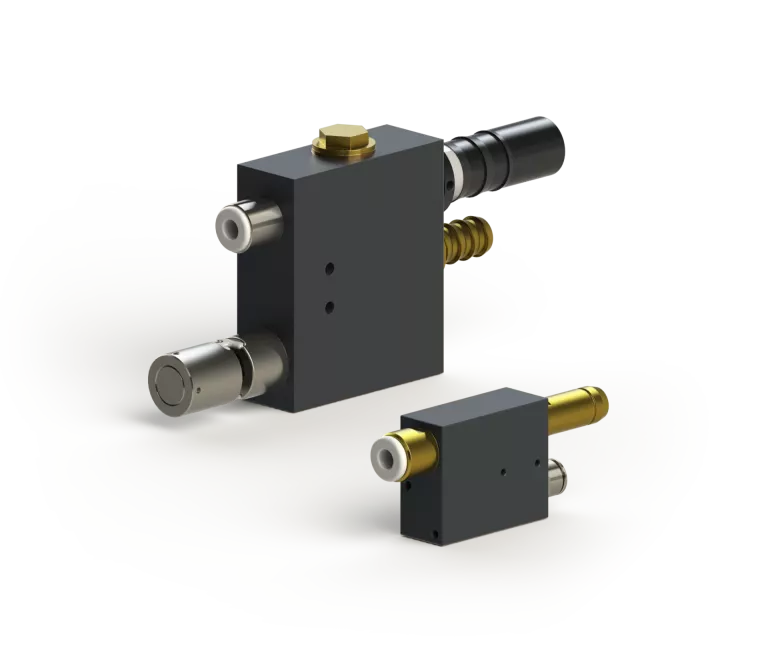

DripDetector

The DripDetector detects thicker sections in a yarn and thus provides information about the condition of the spinneret. Without the DripDetector, the condition is only evident after a significant loss in quality. The DripDetector allows you to perform preventative maintenance on the spinneret.

View Details