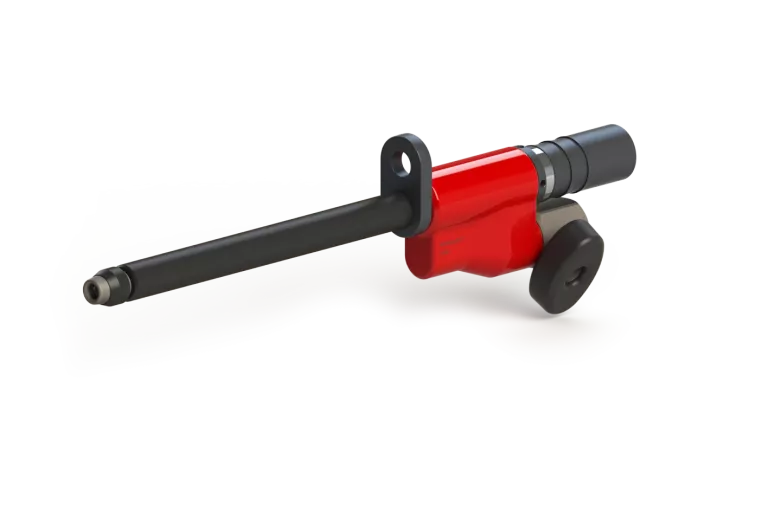

The Lufan-3 is used for threading yarn on textile machines while they are operating. With products for the entire range of yarns and process parameters, our aspirators are in a class of their own. They stand out due to their low weight, extreme durability, and a remarkably powerful suction capacity.

HEBERLEIN. LUFAN-3.

Features and Benefits.

Assortment.

Lufan HS7-3, HS10-3

For high-speed spinning processes of up to 8,000 m/min.

Lufan LC7-3, LC10-3

For spinning processes of up to 5,000 m/min; low air consumption; also suitable for part-oriented yarns.

Lufan HS18-3

For the threading of fibre tows in staple fibre plants of up to 2,000 m/min.

Lufan TF15-3

For rovings, technical yarns, tapes, and mono-filaments of up to 2,000m/min (100,000 dtex at 350 m/min).

Lufan-3 TP Twin-Power

Thanks to the twin system, the Lufan-3 TP delivers even higher suction power with the same pressure. With sufficient suction power, the compressed air network can also be operated at a lower pressure – thus reducing consumption.

Technical data.

Application

| Type | Typical range [dtex] | (Max. limits of application) | Winding speed [m/min] |

|---|---|---|---|

| Textile Yarns | |||

| HS5-3, HS5-3TP | 50 … 1600 | (50 … 3000) | … 8000 |

| HS7-3, HS7-3TP | 330 … 3000 | (50 … 6000) | … 8000 |

| LC7-3 | 330 … 3000 | (50 … 6000) | … 5000 |

| Technical & BCF yarns | |||

| HS10-3 | 1600 … 8000 | (330 … 10000) | … 8000 |

| HS10-3P | 1600 … 10000 | (330 … 15000) | … 8000 |

| HS12-3TP | 3000 … 15000 | (1600 … 20000) | … 8000 |

| LC10-3 | 1600 … 8000 | (330 … 10000) | … 5000 |

| Synthetic yarns in staple fibre plants | |||

| HS18-3 | 3000 … 70000 | (330 … 100000) | … 2000 |

| Different yarns, tapes, etc. | |||

| TF15-3 | 1600 … 25000 | (330 … 100000) | … 2000 |

Air consumption per thread

| Type | Formula |

|---|---|

HS5-3TP, HS7-3TP, HS12-3TP | qvn = 67 x (pe + 1) |

HS5-3, HS7-3, HS10-3, HS10-3P | qvn = 58 x (pe + 1) |

HS18-3 | qvn = 34 x (pe + 1) |

LC7-3, LC10-3 | qvn = 38 x (pe + 1) |

TF15-3 | qvn = 28 x (pe + 1) |

Compressed air requirements

| Max. overpressure |

|

Operating pressure |

|

For the compressed air quality requirements, see Compressed air purity.

Request operating instructions.

Would you like to receive an operating manual for your product? Request now.