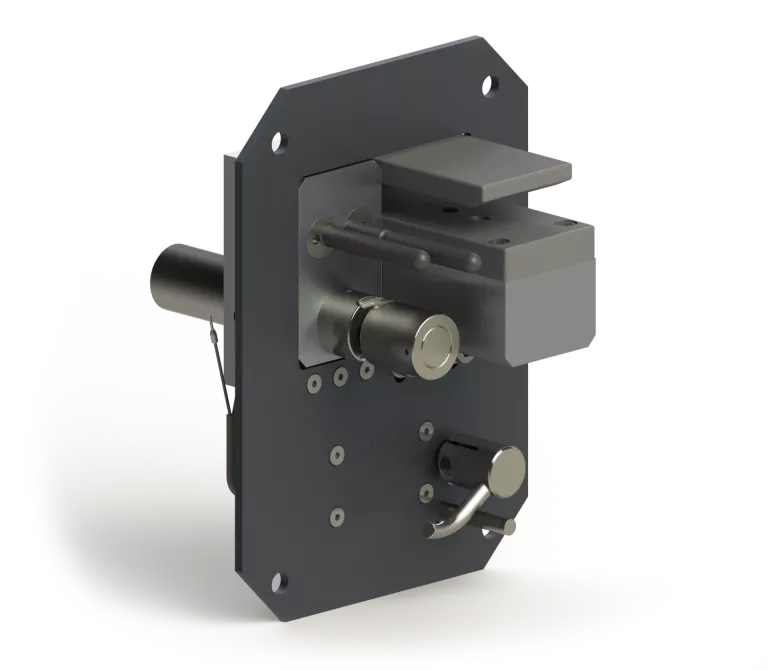

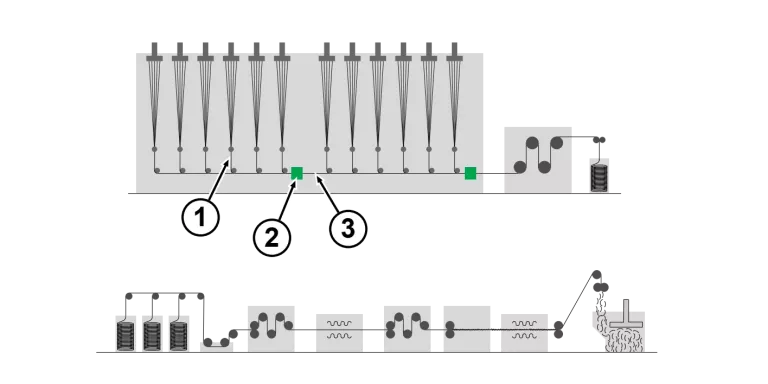

The splicing unit simplifies the handling of individual ends when spinning them in or stringing them up in systems for manufacturing synthetic staple fibre tows. The new end to be threaded is spliced with the general tow in the vicinity of the single spinning position and then cut.

HEBERLEIN. SPLICING/CUTTING UNIT.

Features and Benefits.

Technical data.

Application area

| Type | Distance between splicing plates | Count range [dtex] |

|---|---|---|

081 | 8 mm | … 400‘000 |

101 | 12 mm | 400‘000 … 600‘000 |

13 mm | 600‘000 … 700‘000 | |

14 mm | 700‘000 … 800‘000 | |

15 mm | 800‘000 … 1‘000‘000 | |

1041 | 8 mm | 1‘000‘000 … 1‘200‘000 |

1042 | 8 mm | 1‘200‘000 … 1‘400‘000 |

Air consumption

| Type | Air channel diameter | Formula |

|---|---|---|

081 | 2x 8 mm | qvn = 59.5 x (pe + 1) |

101 | 2x 10 mm | qvn = 93.0 x (pe + 1) |

1041 | 2x 10 mm / 1x 4 mm | qvn = 100.4 x (pe + 1) |

1042 | 2x 10 mm / 1x 4 mm | qvn = 100.4 x (pe + 1) |

Compressed air requirements

| Operating pressure |

|

| Maximum residual oil content (2*) | 0.1 mg/m3 |

| Maximum residual dust content (3*) |

|

| Maximum residual water content (5*) |

|

Request operating instructions.

Would you like to receive an operating manual for your product? Request now.